Cloud native EDA tools & pre-optimized hardware platforms

Developments in optical technologies place ever higher and sometimes completely new demands on the quality of materials, surfaces, components, and systems. Examples include decreasing feature sizes in semiconductor lithography, nanostructured functional surfaces for consumer optics, and advanced optical systems for astronomy and space applications. Demands on materials used in optical technologies require analysis methods that include precise data about a material’s characteristics.

Light scattering measurements can help you meet these demands by providing information about material roughness and surface structures. You can then evaluate the impact of materials on your optical product performance prior to physical prototyping and fabrication. In addition, you can obtain information about how materials interact with light sources by taking into account factors like surface topography, surface contamination, bulk index fluctuations, and bulk particles.

Here are some examples of how light scattering measurements can improve your optical product design.

1. You can quantify product appearance qualities

Quantifying the overall appearance of an object is complicated because appearance is a subjective quality. However, there are specific aspects of appearance that can be quantified with scattering measurements:

- Color from the spectral distribution of light reflected by the material

- Shine from the geometric distribution of light reflected by the material

- Texture from the spatial distribution of light reflected by the material

The quantification of appearance requires establishing correlations between physical quantities and the observer’s response obtained by visual measurements. The physical quantity that integrates this information is called the Bi-directional Reflectance Distribution Function, or BRDF.

A surface’s appearance and optical performance depends on how it scatters light

2. You have access to nano-scale surface roughness data for more accurate product simulations

Scattering measurements make it possible to visualize surface defects such as holes, scratches, grooves, and bumps. As illustrated in the following figure, scattering is dependent on the state of the surface and is impacted by surface defects.

How surface qualities impact light scattering

Depending on the resolution of the scattering measurement device used, you can access surface defects in the nanometer range. This can be very useful for microelectronics and space applications, where defects of this size can have significant consequences and are crucial to detect early in the product development process. Read our Spatial Contamination application note for an example of how we used our specular bench to detect nano-scale surface roughness of a spatial component.

3. You can include real-world volume scattering data in design evaluations

Volumetric scattering is a bulk property of an optical medium that scatters light within the volume of a material. It is typically caused by small particles inside the material.

You can use scattering measurements to obtain volume scattering characteristics of the materials and structures in your optical design – and then include the results in your product simulations. For example, LightTools software can model volume scattering using a Gegenbauer characterization.

LightTools volume scattering analysis using particle parameters from scattering measurements

Optical product specifications are frequently derived from computer predictions that assume idealized surface properties using simple roughness models — and ignore flaws. As we’ve described in this article, BRDF can be impacted by surface roughness as well as material defects, bulk inhomogeneities, and contamination. Measured light scatter data can account for all of these effects. With scattering measurements, optical engineers have access to accurate data for optical simulations, enabling them to gain greater control over product quality.

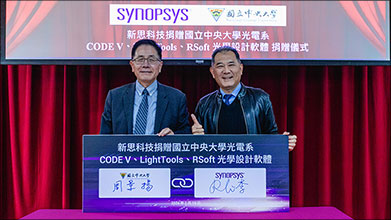

At Synopsys, we offer scattering measurement services that are performed in a light- and temperature-controlled laboratory. This ensures that the measurement process does not skew product simulations by introducing new material defects. In addition, Synopsys measurement services can be performed quickly. This is important for certain types of materials, such as biological tissues, whose condition can change over time.

If you are interested in performing your own scattering measurements, the Synopsys REFLET or Mini-Diff instruments are options to consider. You can export measurement results to optical simulation software, such as LightTools.

BSDF analysis in LightTools illumination design software

To learn more about optical scattering measurements, refer to our application notes, or contact us.